Laser wire stripping is revolutionizing the way we approach wire insulation removal, offering a precise and efficient alternative to traditional methods. Utilizing advanced laser cutting technology, this innovative technique allows for the removal of insulation without compromising the wire’s integrity, making it an ideal choice for both professionals and DIY enthusiasts alike. While many continue to rely on thermal wire strippers or handheld cutters, laser wire strippers are becoming more accessible and affordable, leading to increased interest in automated wire strippers for larger operations. The growing availability of laser cutting tools means that even hobbyists can experiment with this method, further simplifying the DIY wire stripping process. As we explore the benefits of laser wire stripping, it’s clear that this technology is set to enhance both production efficiency and quality in wire processing.

When discussing the removal of insulation from electrical wires, many may refer to techniques like laser insulation removal or high-tech wire stripping solutions. These alternatives not only leverage laser cutting methods but also incorporate innovative technologies that enhance the precision and speed of the stripping process. As the landscape of wire preparation evolves, various tools, including thermal stripping devices and automated systems, are gaining traction in both industrial settings and home workshops. The shift towards these advanced techniques suggests a future where traditional manual stripping methods may become increasingly outdated. Exploring the realm of laser technology in wire insulation removal paves the way for improved efficiencies and higher quality outcomes in electrical work.

Exploring Laser Wire Stripping Technology

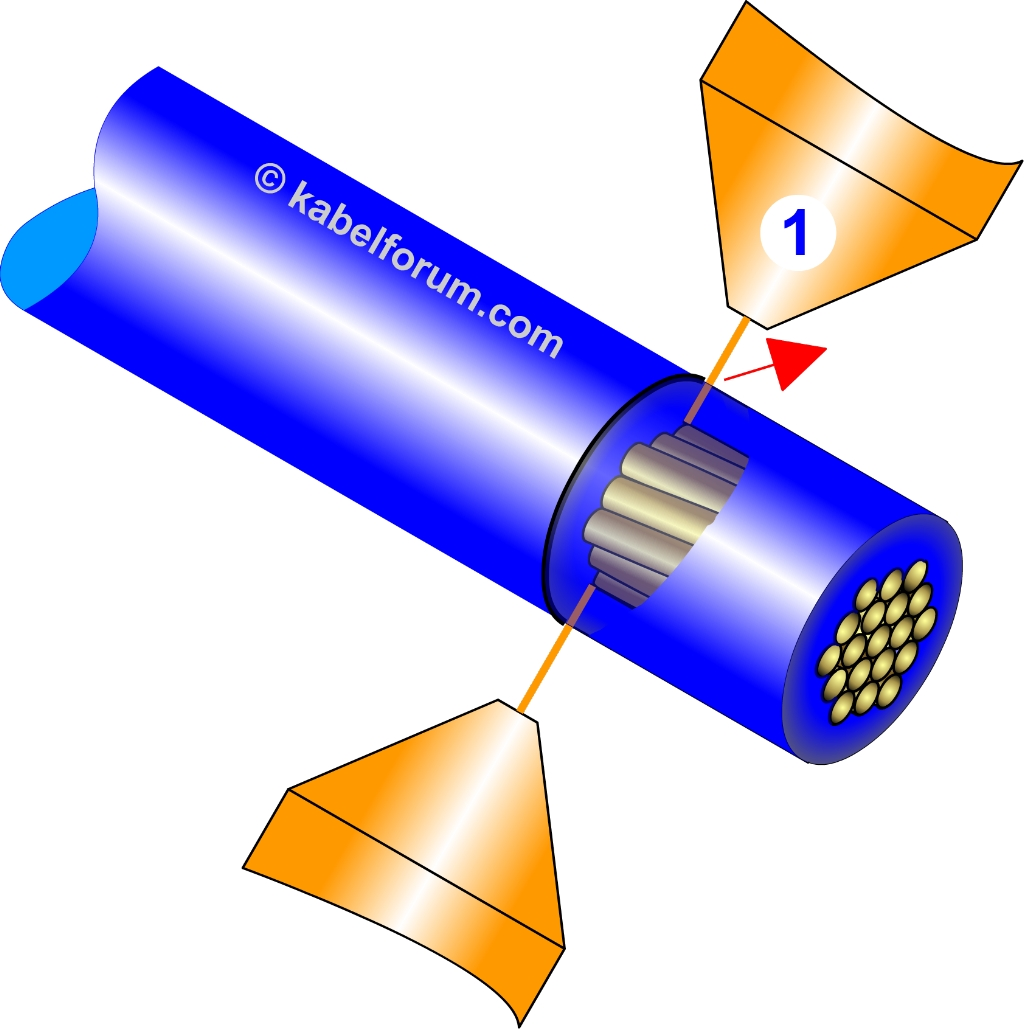

Laser wire stripping technology represents a significant advancement in the field of wire insulation removal. Unlike traditional methods, which typically involve mechanical tools and blades, laser stripping utilizes focused energy beams to precisely remove insulation without damaging the conductive wire beneath. This not only enhances efficiency but also reduces the risk of errors that can occur with manual techniques. With the rise of accessible laser cutting technology, more DIY enthusiasts and professionals are discovering the benefits of incorporating laser strippers into their workflow.

Laser wire stripping provides a clean, reliable way to prepare wires for various applications. The use of lasers means that there is no contact with the wire, which mitigates the risk of mechanical damage often encountered with thermal wire strippers or manual cutting tools. Moreover, the versatility of lasers allows for different types of wires and insulation materials to be stripped effectively, making this method suitable for a broad range of projects, from simple household tasks to complex industrial applications.

The Rise of Automated Wire Strippers

Automated wire strippers have revolutionized the way wire insulation is removed in commercial settings. Designed for efficiency and precision, these machines streamline the stripping process, allowing operators to handle larger volumes of wire in less time. Not only do automated strippers reduce labor costs, but they also guarantee consistent results, which is crucial in manufacturing environments where precision is paramount. As technology evolves, the incorporation of AI and advanced sensors is increasingly common, further enhancing the capabilities of these machines.

While the initial investment in automated wire strippers can be substantial, many businesses find that the long-term savings and increased productivity justify the cost. Additionally, as DIY enthusiasts explore automated solutions, options are becoming available for smaller-scale operations and personal use. This trend is indicative of a broader shift towards technology-driven solutions in tasks traditionally done by hand, welcoming a new generation of makers who are eager to experiment with cutting-edge wire stripping technologies.

DIY Wire Stripping: Traditional vs. Modern Techniques

DIY wire stripping has long been a task performed with manual tools such as cutters, blades, and even improvised options like steak knives. While these tools can get the job done, they often fall short in terms of precision and safety. Modern technology now offers alternative methods, including thermal wire strippers and laser wire stripping, which provide more reliable outcomes. As hobbyists and technicians look for ways to optimize their wire preparation processes, the growth of DIY laser and automated strippers represents a significant paradigm shift.

Adopting new wire stripping technologies can greatly improve the efficiency and safety of DIY projects. Traditional methods may require a steady hand and a good deal of practice to achieve satisfactory results, whereas laser and thermal wire strippers are designed to simplify the process. With reliable heat generation and the ability to cater to various wire types, these tools support a more accessible DIY approach, allowing even novice users to tackle insulation removal tasks with confidence and ease.

Understanding Thermal Wire Strippers

Thermal wire strippers operate on a simple yet effective principle: they utilize heated blades to melt away insulation without damaging the wire itself. This technique is especially useful for delicate applications where traditional stripping methods might cause harm. While thermal strippers are not as widely recognized as their mechanical counterparts, they represent a valuable option for those looking to maintain precision in their work. The straightforward design allows for easy operation, making them an attractive choice for both professionals and DIYers.

Despite their benefits, thermal wire strippers can often be overlooked in favor of more automated solutions. However, the simplicity and effectiveness of these tools cannot be understated. They are typically less expensive than automated systems and can be sourced second-hand at a fraction of the price. As more individuals become aware of their potential, thermal wire strippers could see a resurgence in popularity, especially among those who value hands-on craftsmanship in their electrical projects.

Key Benefits of Laser Wire Stripping Compared to Traditional Methods

Comparing laser wire stripping to traditional insulation removal techniques highlights several significant advantages. One of the most notable benefits is the precision that lasers bring to the table. Unlike mechanical methods, which can sometimes damage the wire or leave residual insulation, lasers offer a clean cut that minimizes the risk of harm. This precision is crucial in applications where even minor damages can compromise the integrity of the electrical system.

In addition to precision, laser wire stripping is often a faster process than traditional methods. The automated nature of laser systems allows for rapid processing of multiple wires, significantly reducing the time required for insulation removal. For businesses and makers alike, this efficiency can lead to increased productivity and reduced costs. As awareness of these benefits spreads, more people are likely to adopt laser techniques in both professional and DIY settings.

Navigating the World of Wire Insulation Removal

Wire insulation removal is an essential skill in the fields of electronics and electrical engineering. Understanding the available methods, including manual and automated techniques, is crucial for anyone working with wires. As traditional methods like cutting and scraping often involve risks of damage, professionals are increasingly turning to more innovative solutions, such as laser technology, for safer and more effective stripping.

For those who prefer a hands-on approach, knowing how to use tools such as thermal strippers can also be beneficial. These devices serve as a middle ground between traditional manual methods and automated machines. By exploring various options available for wire insulation removal, individuals can select the methods that best fit their specific needs and project requirements.

The Innovation of Laser Cutting Technology in Electronics

Laser cutting technology has transformed many industries, including electronics. The application of this technology in wire stripping is a game-changer. By employing high-energy focused beams, laser cutters not only strip insulation but also streamline the entire process, ensuring that wires are prepared efficiently for connections without the need for cumbersome methods. This shift towards precision laser technology demonstrates a commitment to innovation in electrical engineering.

Furthermore, with the growth of DIY culture, enthusiasts are increasingly seeking out laser cutting tools for their projects. As prices decrease and accessibility increases, hobbyists discover the versatility and efficacy of lasers for tasks beyond insulation removal. This wave of interest in laser cutting technology reflects a broader trend of embracing innovative solutions in traditional practices, allowing individuals to achieve professional-quality results in their own workshops.

Environmental Considerations in Wire Stripping Techniques

As with any industrial process, the environmental impact of wire stripping methods is an important consideration. Traditional methods may generate waste materials that require proper disposal, while newer technologies, such as laser stripping, offer a more eco-friendly alternative by minimizing waste produced during insulation removal. Lasers often require less energy than their mechanical counterparts, leading to a lower carbon footprint overall.

Moreover, the fumes produced by laser wire stripping are an important consideration for operators concerned about air quality. While all methods produce some form of emissions, modern laser systems can be designed with ventilation systems that filter out harmful particles, thereby improving safety and environmental responsibility. As companies and DIY users alike become more conscientious about their environmental footprint, adopting advanced laser technologies could be seen as a step towards more sustainable practices in the industry.

Future Trends in Wire Stripping Technologies

The future of wire stripping technologies seems poised for further advancement as innovation continues to evolve. As laser technology becomes more mainstream, it is likely that new applications and improvements will emerge, enhancing the capabilities of laser wire strippers. The integration of smart technologies will likely play a crucial role as well, allowing for seamless operation and feedback systems that automate the insulation removal process.

Additionally, advancements in materials science may lead to new types of wire insulation that are even easier to work with using laser technology. The intersection of laser cutting technology and enhanced insulation materials could further revolutionize wire stripping, making it even more efficient. For those in the industry, staying informed about these trends will be essential to remain competitive and to continue adopting best practices in wire insulation removal.

Frequently Asked Questions

What is laser wire stripping and how does it work?

Laser wire stripping is a process that utilizes laser cutting technology to remove insulation from wires without damaging the conductor. This method offers precision and minimizes thermal impact, making it ideal for delicate wire applications.

How does laser wire stripping compare to traditional wire insulation removal methods?

Unlike traditional methods like thermal wire strippers or manual cutting, laser wire stripping provides a cleaner, more efficient removal of insulation. It reduces the risk of nicks and damage to the wire, which can be common with metal blades.

Can DIY enthusiasts use laser cutters for wire insulation removal?

Yes, DIY enthusiasts can utilize accessible laser cutting technology for wire insulation removal. With the right settings and safety precautions, a CO2 laser cutter can effectively strip wires, making it feasible for home projects.

What are the advantages of using thermal wire strippers over laser wire stripping?

Thermal wire strippers are often more affordable and simpler to operate than laser wire stripping methods. They are effective for basic wire insulation removal tasks but may not offer the precision found in laser cutting technology.

Are there any safety considerations when using laser wire stripping?

Yes, when using laser wire stripping, it’s important to work in a well-ventilated area to manage fumes produced during the process. Additionally, safety goggles should be worn to protect against laser exposure.

What should I look for in an automated wire stripper for high-volume wire insulation removal?

When selecting an automated wire stripper, consider the motor’s power, the range of wire sizes it can accommodate, and its stripping speed. Many options are available that range from basic models to advanced systems for high-volume production.

Is laser wire stripping suitable for all types of wires and cables?

Laser wire stripping is particularly suitable for delicate wires and multi-strand cables. However, the method may not be ideal for very thick or heavily insulated cables, which may require more robust stripping techniques.

Can I use a CO2 laser for wire insulation removal, and what are its capabilities?

Yes, a CO2 laser can be an effective tool for wire insulation removal. It provides sufficient power to strip insulation while reducing the risk of damage to the conductor, making it a popular choice in various applications.

What is the cost difference between laser wire stripping technology and traditional methods?

While traditional wire stripping methods require minimal investment in hand tools, laser wire stripping technology may have a higher upfront cost due to the laser equipment. However, it can lead to cost savings in efficiency and reduced material waste over time.

Where can I find resources for laser wire stripping techniques and equipment?

Resources for laser wire stripping, including tutorials and equipment options, can often be found online in DIY forums, videos, and specialized electronics websites. These platforms provide insights into the effective use of laser cutting technology for insulation removal.

| Tool Type | Description | Pros and Cons |

|---|---|---|

| Metal Blade Tools | Includes cutters, razor blades, and emergency options like steak knives. | Widely available but can be less precise and risk damage to wires. |

| Laser Stripping | Utilizes laser technology for precise insulation removal. | Can be cost-effective and efficient; fumes produced may deter use. |

| Thermal Strippers | Involves two heated blades to strip insulation. | Less common despite being low-tech; can be expensive unless used. |

| Automated Stripping Equipment | Powerful machines for high-volume stripping. | Costly but effective for mass production; requires investment. |

Summary

Laser wire stripping offers an innovative and efficient solution for the removal of insulation from wires, utilizing advanced laser technology. This modern method contrasts with traditional techniques that depend on metal blades. While many still rely on basic tools like cutters and blades, laser stripping is gaining traction, particularly in assembly line environments. Although initial costs may be high, users can find affordable options in the surplus market or through DIY setups. Overall, laser wire stripping demonstrates significant potential, despite its current underutilization in smaller operations.